SPOT LINERS: A NO-DIG REPAIR OPTION

Pipetek Infrastructure Services has a no-dig, cost effective repair method for deteriorated and problematic sewer pipes. Using a method referred to as Cured-In-Place-Pipe (CIPP), Pipetek can install a Spot Liner to restore structural integrity, increase flow capacity and reduce infiltration in a compromised sewer line. This efficient, long-lasting “trenchless” method eliminates the high cost, large footprint, dangers, and time-consuming process of open cut excavation.

BACKGROUND

When you talk about the infrastructure, the first thing that comes to mind for most people are the roads. In the Midwest, potholes and deteriorated roads are common and top of mind because we see them everyday, but what about the world underneath these roads? The average lifetime of a road is 18-25 years before it’s replaced, yet most sewer lines across the country are well over 45 years old. Similar to the roads, many sewers are constructed of cementitious materials or natural aggregates that deteriorate overtime. This can result in cracks or fracturs in the pipe (decreases structural integrity), points of infiltration (possibility of a sink hole or increased treatment cost), separated / offset joints from ground setting (resulting in debris buildups and blockages). When the sewer line contains defects similar to the ones mentioned above, a rehabilitation plan is necessary to prevent failure and disruptions to the system. While there are many rehabilitation methods, they are commonly separated into two categories – Dig and No-Dig.

The most common No-Dig method is CIPP Lining. CIPP lining uses a textile liner tube and resin to cure the material to the surface of the existing pipe, restoring flows and structural strength. CIPP lining can be performed for various lengths and diameters. When there are a minimal number of defects in a line or they are centralized in a given area of the pipe, the cost-effective option is to install a CIPP Spot Liner at those given areas. By repairing only the areas of the pipe that require rehabilitation, there are advantages over using a full length liner - saving time, investments, materials and hours of labor.

The CIPP Spot Liners that Pipetek installs exceeds the CIPP Specification ASTM F1216 and restores structural integrity to damaged pipes. The liner creates a pipe within a pipe, the fully cured resin and fiberglass serve as a structural barrier between the interior of the pipe and the exterior environmental conditions. Additionally, the product meets NSF and ICC-ES-PMG specifications. This trenchless technology has been tested and proven to withstand pressure, extreme conditions, and time to ensure that the pipe is rehabilitated and preforming exceptionally for years to come.

Pipetek’s Process

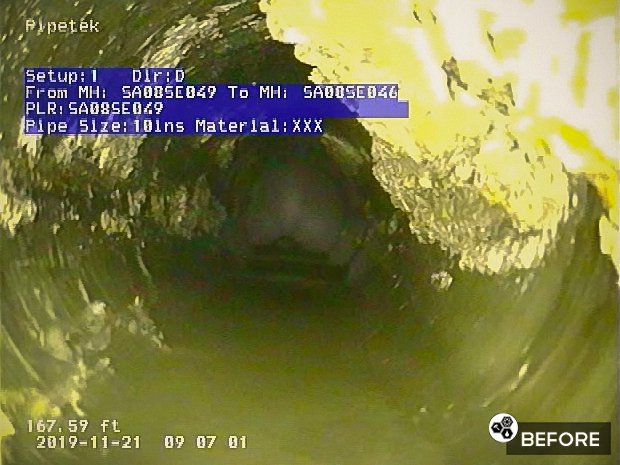

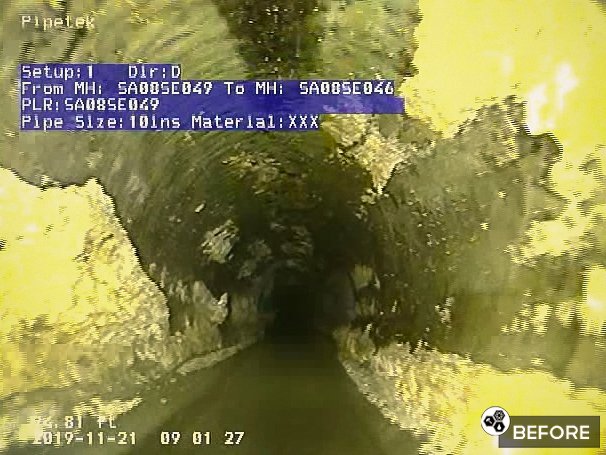

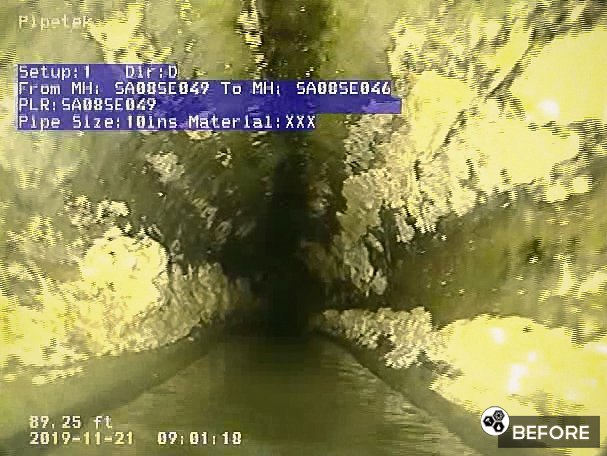

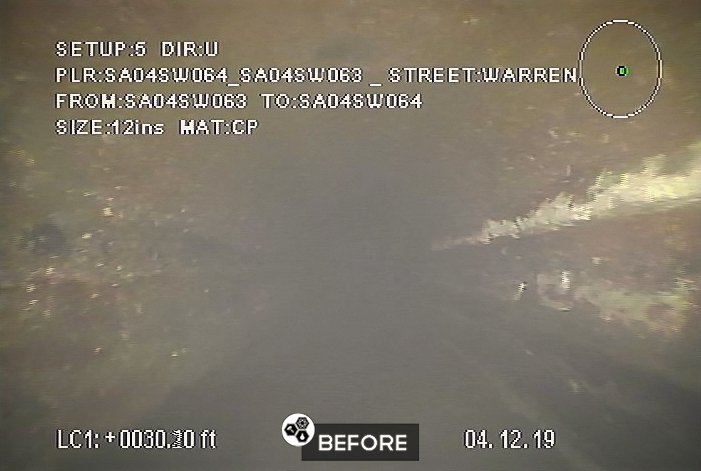

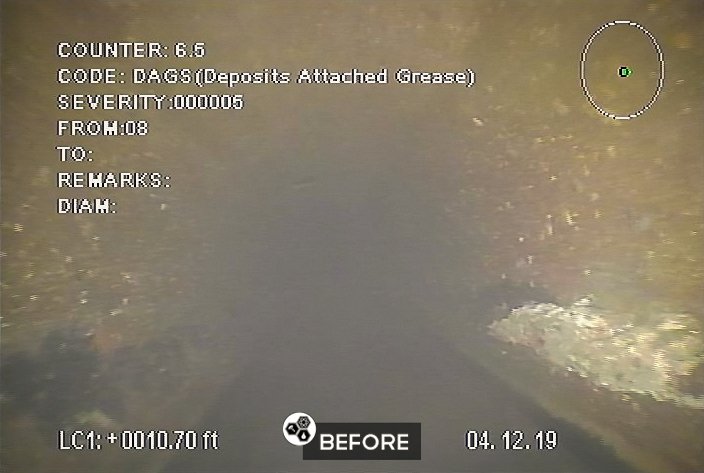

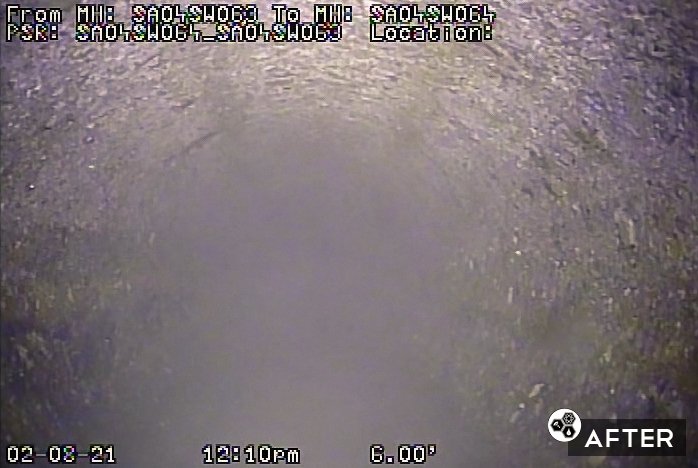

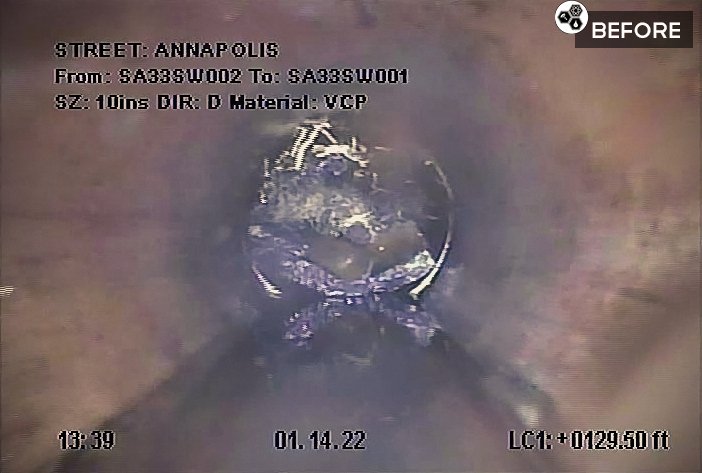

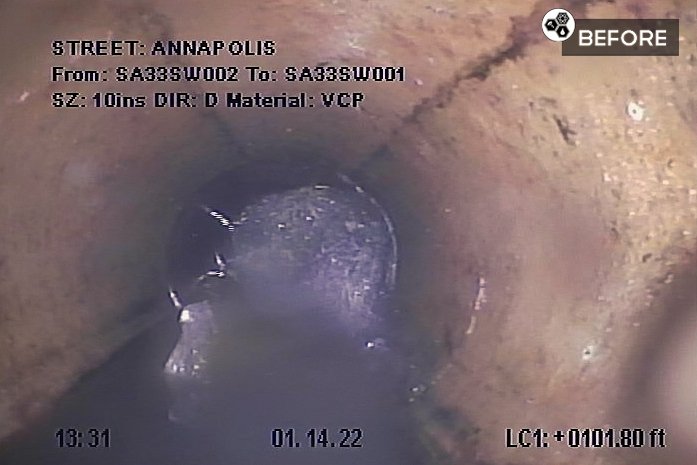

Pipetek operates many CCTV Inspection and cleaning crews for various contractors and municipalities. While on these projects, we use a sewer camera to inspect the interior conditions of pipes. Following NASSCO standards while coding and identifying defects in the sewers, we come across problematic areas that are good candidates for spot liners. Using the CCTV data and locating the defect with a footage counter and above ground locator, we can share the data with our clients and present them with a solution.

Once a plan is shared and approved with our client, we begin the “prep” process. This involves a thorough cleaning of the pipe, removing any obstructions (roots, calcium buildups, settled debris) so our CIPP Liner can adhere to the walls of the host pipe and restore full capacity of the pipe.

Each spot liner consists of a fiberglass fabric coated with an epoxy resin. We wrap the liner tightly around an inflatable rubber installation packer. The packer and patch are then pushed or pulled through the pipe to the problem area using a cable or our tractor. Once in place, we inflate the Packard using an airline to our compressor to a predetermined pressure. Pipetek has flow-through packers which allow the spot liners to be installed without the use of a bypass system. Inflating the Packard pushes the patch against the inside of the host pipe. The packer and host pipe work together to act as an impromptu form for the patch. As the resin cures, it hardens the fiberglass fabric into a solid pipe within the host pipe. In this way, the patch lines the section of the pipe, seals off all leaks, and becomes a structural repair. The cure time of the patch varies based on environmental temperatures, but once cured, the packer is deflated and retired.

CURRENT PROJECT

Pipetek is currently working on two spot lining projects – Oakland County Water Resource Commission (WRC) and City of Southfield with Inliner Solutions. On each of these projects, the sewers were initially cleaned and inspected following NASSCO standards. After the inspections, a review was conducted on the municipalities’ behalf to determine compromised pipe that would be suitable for potential CIPP Spot Liners. From there, the Pipetek team works with the end customer to develop the rehabilitation recommendations using CIPP Spot liners.

Pipetek has recently installed over fifty (50) spot liners ranging in diameter of 8”-12” in various cities for Oakland County WRC. These spot liners were able to repair defects such as void/hole, broken pipe, joint separation, offset joint and, in the end, increase the life of these sewer lines at an affordable price. In Southfield, Pipetek is assisting Inliner Solutions on a similar project where initially over 100,000 linear feet of pipe was inspected and an evaluation of the condition was performed. After this review, it was determined that approximately 130 pipe segments could be rehabilitated using the CIPP Spot Liner technology. Ranging in pipe size of 8” to 27”, Pipetek will install over 130 spot liners ranging in length of 3’ to 20’ to assist in repairing and prolonging the lifespan of the sewer system.

The Pipetek team has enjoyed the opportunity working with various municipalities, contractors and engineering firms on these projects. Our team members always feel great seeing the impact they are making to improve the infrastructure and satisfying our customers.