Understanding Cross-bore inspections

What is a Cross-Bore?

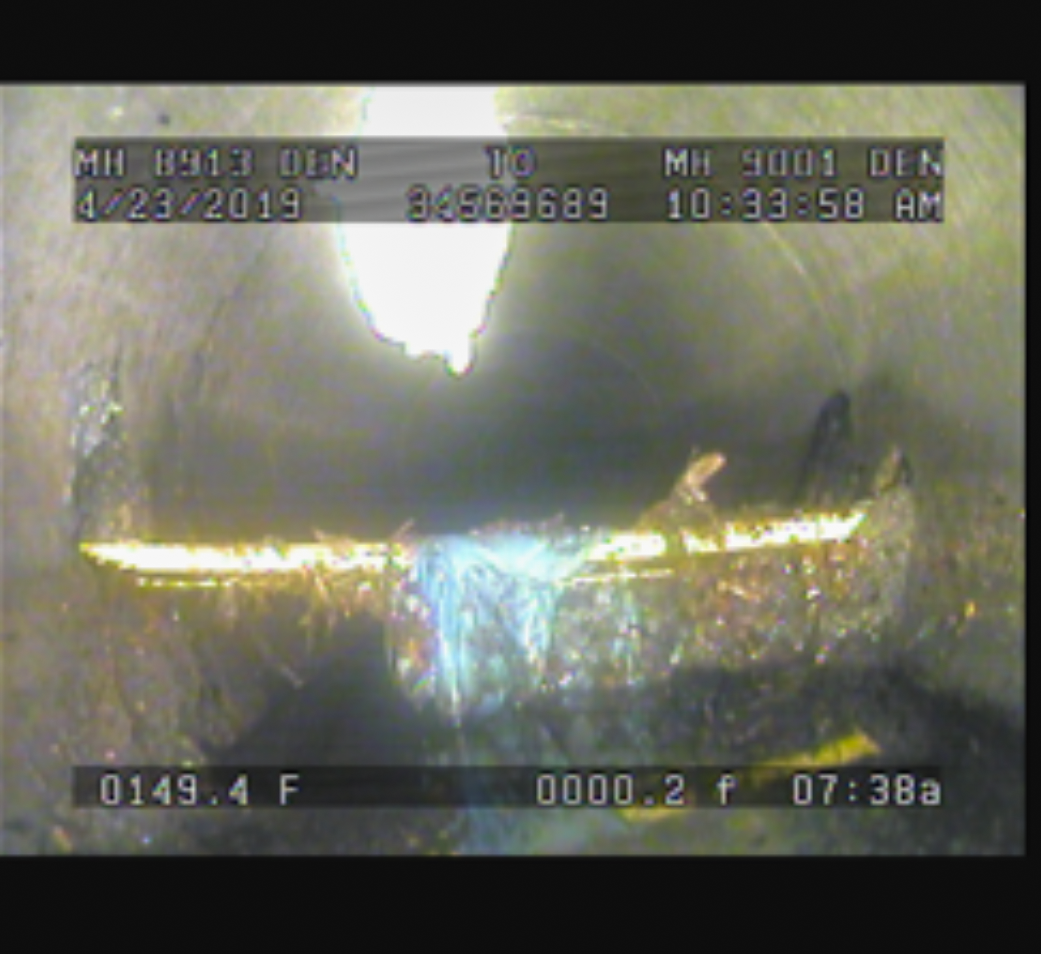

A cross bore is a utility that has been directionally drilled through a sanitary or storm lateral. The utility could include electric, communications, water, and most importantly gas.

A gas service or main can potentially be directionally drilled through another lateral or main. Why is this so important you ask? The service could be inserted without the building owner being aware for months, or even years. If there is gas inside of the lateral and a plumber augers the line, there is potential to damage the gas line and have gas migrate back into the house. Any type of ignition could spark and, in the worst-case scenario, have the home or structure explode.

Inspection Types

PRE-INSPECTION

A pre-inspection is televising the lead or main with a CCTV system. This inspection will depict the location and depth. Typically, at the main, curb, property line, and foundation. Wooden stakes are left in the yard for a visual and a drawing of the parcel can be included.

POST-INSPECTION

A post-inspection is performed after the directionally drilled utility is installed. This visually verifies there is not a cross-bore. In the event there is a cross-bore, it is documented with paint and pictures of the damage. The owner of the utility is also informed immediately.

Pipetek’s Cross-Bore Prevention Program

Pipetek offers pre- and post- inspections across various municipalities – from large scale installation projects to single addresses. In the event an inspection cannot be performed with a Lateral Launch System, our skilled house entry crews can perform the inspection from an internal or external clean out, pulled toilet, or roof vent. All inspections include a drawing of the parcel, video, and pictures. This information is stored on our ArcGIS platform to keep historical record to show areas where this risk is higher.

The following images are provide for visual examples of cross-bore situations: